Business Here is an overview of Okudasokabe's business activities.

Okuda Sogabe Co., Ltd. is a specialized manufacturer of metallic bellows type expansion joints and services more than 1,000 companies in the major industrial sectors.

- Power Industry

- Crossover Piping in Steam Turbineetc.

- Oil & Gas

- Fluid Catalytic Cracking Units (FCC)etc.

- Steel Miller

- Dome Transfer Lineetc.

- Petrochemicals

- Styrene Monomer Plantetc.

- Water Pipe

- Water Pipe Bridge & Dametc.

- Others

- Piping in various plantsetc.

Inspection and maintenance support

As an after sales service, following technical support for client in terms of maintenance works is available

● Supervision at site installation

● Periodical inspection at site/ technical proposal for integrity enhancement

● Supervisor dispatch.

● Destructive inspection including service life inspection using a repeat testing machine and Non-destructive inspection

etc..

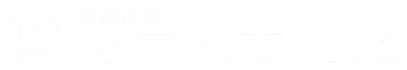

■ Prevention of broken-down and/or leakage of bellows by testable bellows with a detector (Preventive Maintenance)

A damage generated in the inner ply of the bellows can be detected without leaking to the outside, which thereby enable to use for a certain period of time after the leak is confirmed. It prevents emergency shutdown of equipment and ensures lead time for production of replacement products and improvement measures, which leads to various solution of problems. In addition, the multi-ply sealing structure protects corrosion of the outer ply with an inner layer, and extends the life. In important equipment such as FCC and SM equipment, testable bellows with a detector are recommended for stable operation, and we have many achievements in Japan and overseas.

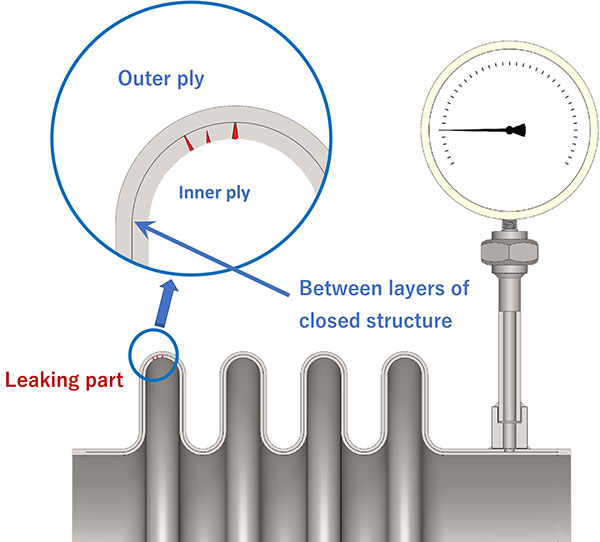

■ Early restoration by the clam shell method as a temporary site repair (Corrective maintenance)

When the expansion joint is damaged, recovery is required in as a short period of time as possible. When the broken expansion joint is with lining for insulation and antifriction purpose and/or installed in a too narrow space to replace, the clam shell method is effective to repair. The clam shell method for the existing broken expansion joints support the safe operation till the next turnaround by the temporary repair at site

This repair method is that bellows divided into two portions in the longitudinal direction are welded on the outside of the existing bellows at site.